In This Issue: 1. Cover Story – DynaROCK II. Universal Rebound Hardness Tester 2. Special – 15% OFF any BAQ Hardness Tester 3. News – New Helmut Fischer website 4. Applications – Compliance – Coating Thickness inside storage tanks

The dynaROCK II works according to the Leeb rebound hardness test method for metallic materials. It is The dynaROCK II combines easy operation with high precision and reliability. For different applications, • Fast and easy hardness testing • Measuring method according to DIN 50156 and ASTM A956 • Robust metal casing • Large colour display • Embedded Li-ion battery • 12 groups of materials • Extensive storage and statistical functions • USB interface and PC software • Made in GERMANY Type D: Impact device for most hardness testing tasks Type DC: Extremely short impact device -access or pipes Type C: Reduced impact energy e.g. hardened parts Type D+15: For small placement surface Type DL: Impact device with longer impact body Type G: Impact device with increased impact energy

Like A Price – 02 8850 3755

15% OFF any BAQ Hardness TesterLike more information – 02 8850 3755

Like more information – 02 8850 3755

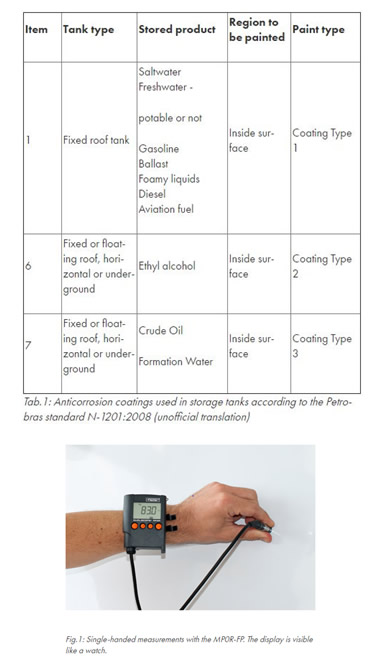

Anti-corrosion coatings on the interior of storage tanks are critical when storing many types of products, whether salt

Although there are many such regulations, the Petrobras standard, N-1201:2008 – “Anticorrosion Coatings for the

4.2.1 Coating Type 1 4.2.3 Coating Type 3: one layer of non-solvent epoxy Once they are applied, the coatings need to be inspected – a tricky Since a handheld gauge with integrated probe will not work, as most

FISCHER developed the MP0R-FP products for just such applications performed under difficult conditions. While MP0R-FP series calibration can be also be done outside the tank using FISCHER calibration accessories and a The unmatched accuracy and repeatability performance of the MP0R-FP series from FISCHER make the ideal choice Like the Petrobras standard N-1201:2008 for storage Tanks.

Have any questions or like further details?; Ph 02 88503755 or Email

|

The Best in Quality Service and Products for Non destructive testing