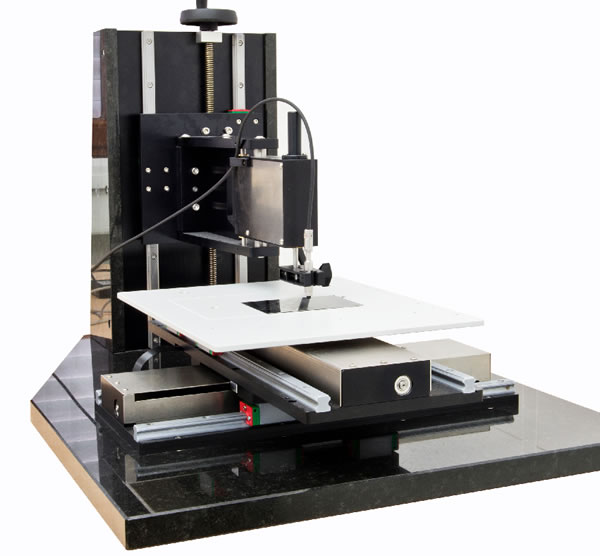

For automated coating thickness measurements with tactile probes using precise, programmable positioning

The Automated Measurement Table has been especially developed for automated coating thickness measurements for various applications, e.g. to check the uniformity of a paint layer such as paint/steel or paint/aluminum or to check many single samples in a holder, e.g. coating of screws.

The well-proven tactile probes from FISCHER are used for taking the measurements. The probe is hovering over the table which can move in X- and Y-direction. As soon

as the table reaches its position, the probe is lowered in a motor-driven manner and a measurement is taken.

The Automated Measurement Table is controlled by the universal Multi-Measuring System FISCHERSCOPE® MMS® PC2.

Typical fields of application:

• Automatic measurements at pre-programmed positions (as a grid or along a line) where reproducible, precise positioning of the probe is required. Hence, the uniformity of the coating can be checked.

• Automatic measurements on many samples in a holder. Hence, the manual effort is not only reduced but the measurements have also been taken in the very same way (reproducibility) which ensures accurate measurements.

• Manual measurements by moving the table to the required position using the joystick and then taking a measurement.