|

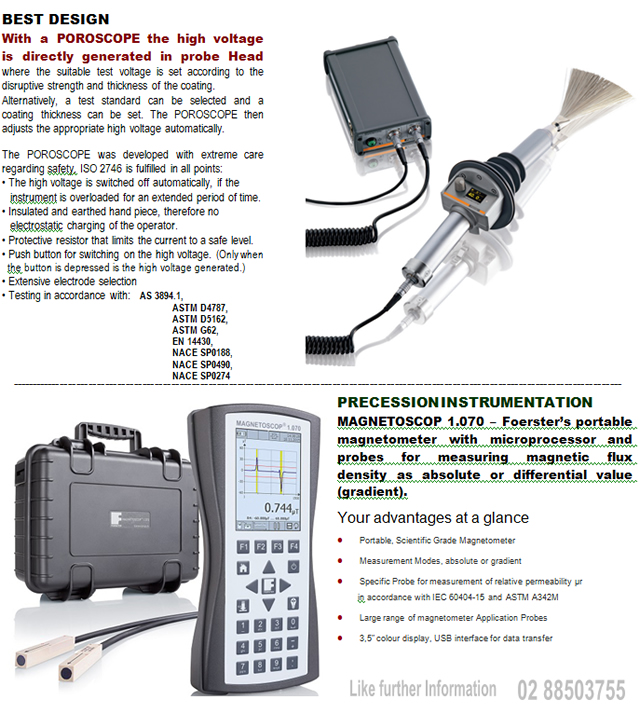

In This Issue: 1. Cover – Echometer 1076TC. Through Coating Gauge 2. News – From the Sales Desk – POROSCOPE HV5, HV20, HV40 – high voltage generated in probe Head MAGNETOSCOP 1.070 – magnetometer, magnetic flux density as absolute or differential 3. Special – 10% OFF Echometer Wall Thickness Gauge 4. Application – Heat-Treatment Control of Aluminium Components

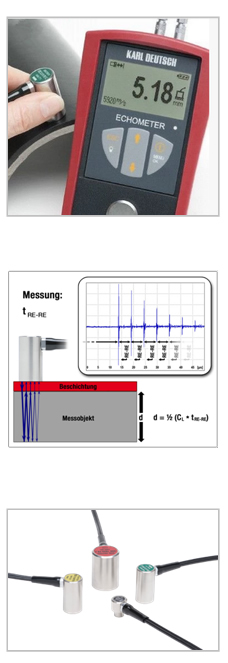

Ultrasonic Wall Thickness Measurement – Even Through Coated Material

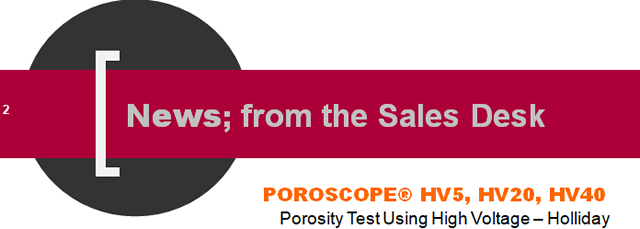

The second major field of application is the standard material thickness control in production and maintenance where tight tolerances are to be fulfilled. The new highly sensitive 5 MHz standard composite probe has a measuring range of 1.2 mm through 250 mm in steel. Using the new high frequency 10 MHz probe the lowest thickness can come down to 0.5 mm and goes up to 400 mm when connecting the 2 MHz transducer. Furthermore by connecting a calliper to the instrument the speed of sound can be determined if unknown. Customers appreciate this unique capability to check the nodularity in cast iron parts (as a function of speed of sound). In “Through Coat” mode the 5 MHz standard probe is used with a measuring range of 2 mm through 28 mm in steel (with coatings up to 6 mm thickness). Thickness variations of the coupling layer as well as temperature drifts during the measurement work cannot affect the result due to consecutive back wall echo measurements. Thus, the re-calibration of the probe on a reference plate is no longer necessary. To validate the signal quality KARL DEUTSCH has developed an innovative coupling verification where clear measurement results through varnish or paint can be achieved. Additional checks are done in order to avoid incorrect measurement results on complex geometries or the impact of rust (on the rear side of the component) respectively. Karl Deutsch software iCom is used to configure the ECHOMETER 1076 TC which has an intelligent data management. The system is network-compatible and enables the data transfer into almost every PC format. The possibilities of remote control and comprehensive documentation make iCom an ideal tool for companies with a wide range of testing and measurement tasks as well as for process chain verification within quality audits of costumers. The device can also be integrated to a CAQ system via another KARL DEUTSCH software “EasyExport”. Still Made in Germany

Like more Information – 02 8850 3755Like more Information – 02 8850 3755

Like more Information – 02 8850 3755

Have any questions or like further details?; Ph 02 88503755 or Email

|