In This Issue:

- Cover Story – New Model SIGMATEST 2.070 Conductivity Meter

- Special – 15% OFF Calibration Foils

- News – Magnetoscop 1.070 / Magnetic Powder Blower PB-1e

- Applications – Quality control of Razor Blades & Scalpels

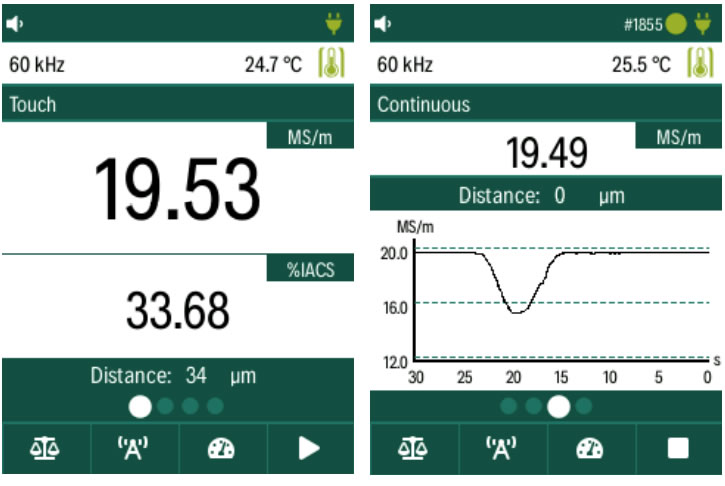

SIGMATEST Operating Modes

The SIGMATEST 2.070 is capable of operating in either

TOUCH or CONTINUOUS mode.

Use CONTINUOUS mode to scan surfaces and display the measurement values in a time chart or,

Use TOUCH to measure single values.

Use the recording function to save all measurements.

SIGMATEST advantages at a glance

▪ The SIGMATEST 2.070 has Easy operation

▪ Wide frequency range to measure several material thicknesses

▪ Temperature compensation for stable results, even at variating Temperatures.

▪ Automatic distance compensation up to 0.75 mm for Measurement of items in bags or through paint.

▪ Correction factors for measuring on curved surfaces.

▪ Increased measurement accuracy also at high frequencies of (480 kHz) of +/- 0.5 %.

▪ Shielded probes to avoid edge effects.

▪ Long wearing probes with optional titan protection.

Higher test accuracy with Sigmatest 2.070

▪ The SIGMATEST 2.070 offers frequencies of up to 960 kHz. This high frequency makes it possible to perform accurate electrical conductivity measurement on very thin test pieces.

▪ Probe characteristics are now directly saved within the probe and automatically read by the device.

▪ SD-card slot for saving nearly an unlimited amount of test data.

▪ Remote control by an external PC is possible via Ethernet standard RJ45. The interface allows complete control over the instrument and an integration in automated systems.

▪ The operator interface supports multiple languages.

15% OFF

Calibration Foils

For Coating Thickness Reference and Calibration on Ferrous or Non-ferrous metals or

over Customer’s own samples; whether Round, Curved or Flat *(thickness relevant)

The Magnetoscop from Institute Dr Foerster, (Foerster Group) is the Portable microprocessor-controlled magnetometer system for Measurement of magnetic flux density weather absolute or gradient & Permeability.

Probes for measurement of relative permeability µr in accordance with IEC 60404-15 & ASTM A342M

Stds; ASTM A342M, API Spec 7, AEODP-7, IEC 60404-15, STANAG 2897, VG 95578

MAGNETOSCOP 1.0703 – Available Complete Kits;

- Field- & Differential-Measurement

- Field- Measurement

- Field- Measurement Hall Transversal

- Field- Measurement Hall Axial

- Differential- Measurement 100 mm

- Differential- Measurement 20 mm

- Permeability- Measurement

- Hot Spot Testing including Software

MAGNETOSCOP 1.070

Portable Magnetometer

Magnetic Powder Blower

PB-1

Description

The PB-1 Hand-held Controlled Magnetic Powder Blower provides reliable and controlled application of magnetic inspection powder to areas previously inaccessible – horizontal, vertical and overhead.

The hand-held PB-1 incorporates a unique magnetic control for precise adjustment of powder quantity. Powder is gently floated in a complete and uniform mix of all particle sizes to the test surface.

The one-pound capacity bottle fits operators hand comfortably to enhance application.

Quality control in production of Razor Blades & Scalpels by using Saturation Polarization method (SP).

In steel manufacturing, the final products (whether raw materials or semi-finished parts) often contain a number of material phases, e.g. austenite, ferrite and martensite. The correct proportion of the various phases increases the desired mechanical properties of the material used. For example, martensitic steels are broadly used for applications where wear and edge-holding resistance are highly required, such as the manufacturing of razor blades or scalpels. The phases can be analysed using electron/optical microscopy or X-ray diffraction methods.

But, unlike these methods, the saturation polarization (SP) approach of the KOERZIMAT 1.097 not only requires little to no specimen preparation but also delivers very quick and precise analyses. This KOERZIMAT 1.097 method is best suited when the material contains only a few phases.

In stainless steels, for example, the martensite, ferrite and austenite phases are all present in various proportions (e.g. duplex or ferritic stainless steels). Each phase is catalysed by a certain alloying element: For example, Cr is a ferrite phase creator, whereas Ni is an austenite stabilizer. The magnetic phases have mechanical properties (hardness, porosity, brittleness) that can be undesirable for some applications; in this case, it is important to know the percentage of martensite and other magnetic phases. Here KOERZIMAT 1.097 SP provides fast and precise monitoring of the magnetic phase, both during manufacturing (after thermal treatments and cold working) and at incoming goods inspection. In terms of their magnetic properties, martensite, bainite and ferrite have a clear ferromagnetic nature, whereas the austenite phase is “non-magnetic” (paramagnetic). This physical difference plays a key role in the KOERZIMAT 1.097 SP approach, since the measurement of SP makes it possible to determine the percentage of magnetic phases in the tested material.

Industry: Steel manufacturing, razor blades & scalpels

Material/Part type: Martensic stainless steel

Measuring parameter: Magnetic dipole moment

Industry standard: IEC 60404-14

FOERSTER device: KOERZIMAT 1.097 MS

FOERSTER’s KOERZIMAT 1.097 MS measuring system enables

fast determination of magnetic phases based on the SP method. The underlying method of the device can be generally described by the following formula:

MP= S/M ×100%,

where MP is a magnetic phase to be determined (in %), S is a weight-specific saturation polarization measured using the KOERZIMAT device and M is a theoretical value of the weight-specific saturation polarization associated with only the magnetic phases of the steel being tested. To compute M,

the KOERZIMAT MP software module requires the following information:

■ Mass portion (in %) of the various alloying components, available during production

■ Percentage of carbide, from information collected through metallographic analysis typically done once before production for each alloy.

The advantage of integral measurement with this system is that it requires no specimen preparation, and at the same time offers full flexibility for the shapes to be tested.

For the determination and analysis of the magnetic and austenitic phases of steels, we recommend the KOERZIMAT 1.097 MS system.

For further information please visit our Website;