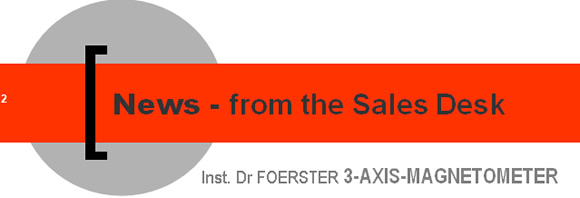

|

In This Issue:

1. Cover MPI Through Galvanizing 2. News 3-AXIS-MAGNETOMETER Made in Germany -Magnetic Yoke 3. Special 15% OFF Deutropuls Yokes 4. Application Compressive strength testing: a Single Strand Carbon Fibre

This Magnetic Yoke by Karl Deutsch of Germany, ‘DEUTROPULS’ now has New attachment poles specifically designed to ensure reliable magnetic particle testing through hot-dip galvanizing and thus permits testing in compliance with DASt 022:2016. DEUTROPULS geometrically optimized attachment poles enable increased field strength of more than 4 kA/m (40 A/cm) achieving magnetic particle testing of weld seams through the galvanized coating. The magnetizing time and the post-magnetizing time is 6 seconds each.

Like more Information – 02 8850 375515% OFF Until March 31st Any Deutropuls Magnetic Yoke Like more Information – 02 8850 3755

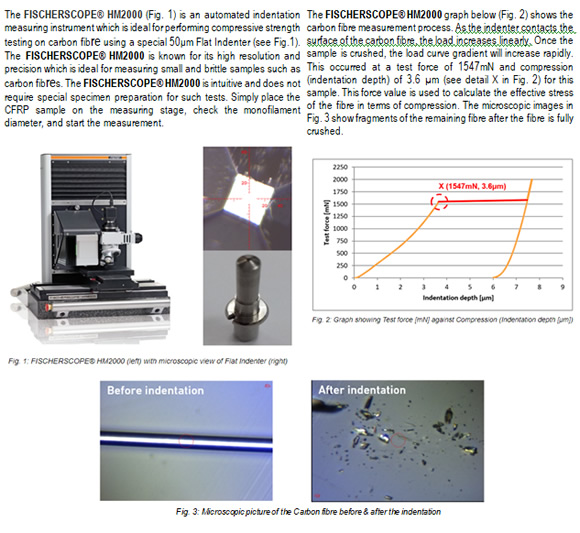

Carbon Fibre Reinforced Plastic or Polymer (CFRP) is known for its high strength to weight ratio, excellent high-temperature characteristics & fatigue resistance. CFRP has gained substantial interest in aerospace, automotive, marine and civil engineering. Carbon fibre is the backbone of CFRP and is responsible for its strength. Each carbon fibre is a long thin strand made of thousands of carbon filaments with a diameter of 5-10μm. The compressive strength of carbon fibre is significantly less than its tensile strength. Thus, in industry applications, axial compressive strength is usually used as the basis for its design rating. This ensures its safety and functionality.

Have any questions or like further details?; Ph 02 88503755 or Email

|

The Best in Quality Service and Products for Non destructive testing