In This Issue:

- Cover Story – MAGNETOMAT, German made PC-controlled Magnetometer

- Update – RECHARGABLE Karl Deutsch UV Lamp Now Available

- Applications – Helmut Fischer Accredited Market Leader.

The MAGNETOMAT 1.790 from Institute Dr Foerster of Germany.

is the PC-controlled 4 channel magnetometer system suitable for applications in the area of precise determination of magnetic flux density and magnetic permeability. MAGNETOMAT is suitable for measuring static or low frequency dynamic magnetic fields. Depending on probe type and selected application software, the following measurements are possible:

¾ Magnetic flux density as absolute value up to 100 μT or gradient up to 200 μT

¾ Relative magnetic permeability μr in the range 1,00000 to 2,00000

The MAGNETOMAT is operated either as a benchtop unit or for integrated automation applications

A range of different probes to suit versatile applications and test standards are available.

The Software MAGDATA is utilised for setting the parameters, real-time display of the test results, data sampling and report generation.

Up to 6 I/O interfaces can be used and programmed by the operator for automation tasks without additional control.

MAGNETOMAT Applications

¾ Long term monitoring of magnetic environmental conditions, e.g. prior to installation of magnetic sensitive devices like MRI systems.

¾ Testing low permeability materials and machined components for magnetic remanence.

¾ Detection of ferrous inclusions in austenitic steels and nonferrous alloys.

¾ Determination of relative magnetic permeability as part of the quality inspection for austenitic steels and non-magnetic alloys.

¾ Verify the nonmagnetic property of components for integration into magnetic sensitive devices.

¾ Verify material changes caused by high temperature, corrosion, coating reduction or micro structural Alteration.

¾ Integration in automated measuring and testing devices.

GERMAN MADE

RECHARGABLE UV-LED LAMP

Review at a Glance:

The Karl Deutsch model 3817.001 UV Lamp uses One LED white light and Five intensive high-performance UV LEDs with a service life of more than 10,000 hours. Switching to white light mode at the touch of the secondary button.

The lamp is hand made in Germany and complies with DGZfP requirements, in particular regard to Wavelength & Intensity.

The 3817.001 meets the standards, among others: ASTM E 3022, Airbus AI TM 6-1001 & Rolls Royce RRES 90061.

After switching on, the lamp is immediately ready for operation. It has a high UV intensity and a uniform intensity distribution.

Key Facts

- Light and ergonomic

- UV intensity: 45 W/m² or 4,500 μW/cm² at 380 mm distance

- Large UV light field: Ø 280 mm at 380 mm distance (> 10 W/m² or 1,000 μW/cm² according to ASTM)

- UV-A radiation with 365 nm wavelength

- No danger from UV-B and UV-C radiation

- Rubber frame on the lamp head for shock protection and for a safe stand when placed down not in use.

- Dust-tight and splash-proof (IP64)

- Due to the low operating voltage, there is no risk of electric shocks when testing in closed containers

- Approx. 3.5 hours continuous battery operation

- Optional: power supply unit with oil-proof connection cable

Trust the number 1 ‘Helmut Fischer’:

World’s best in Measurement Technology and Service Performance.

You know you’re getting the best when you see: ‘Made by FISCHER’!

Making our customers world measurably easier: This has been Helmut Fischer’s corporate goal since 1953. We develop precisely tailored, intelligent measurement solutions in the areas of coating thickness measurement, material analysis, Nano indentation and scratch testing. The portfolio is diverse: from handheld devices for fast coating thickness measurement in corrosion protection, to XRF spectrometers for precise gold testing, or XRF analysis in electroplating to fully integrated high-end systems in the electronics industry.

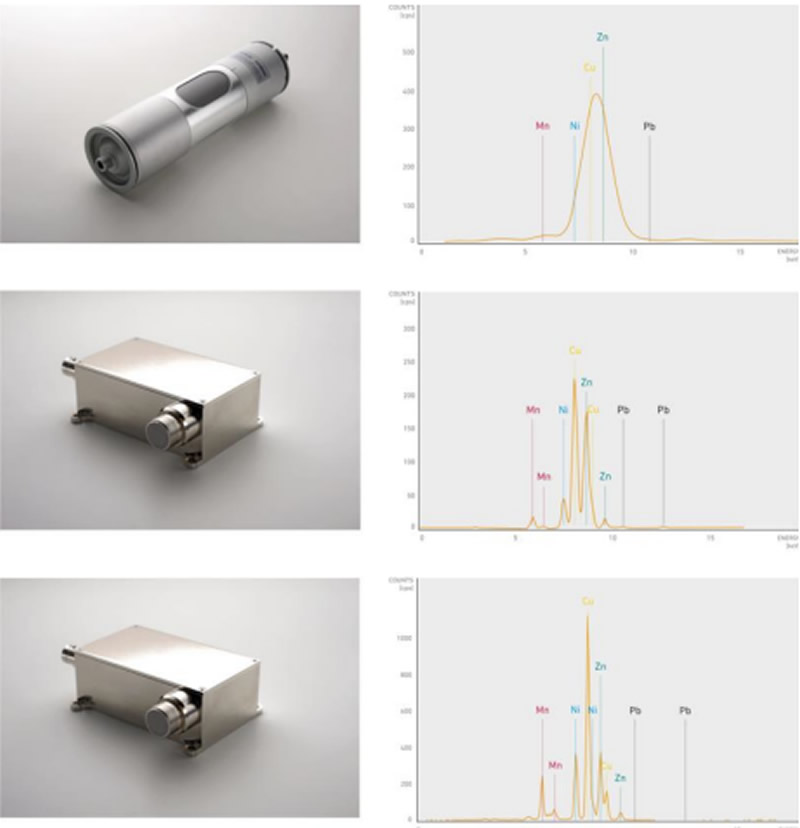

Most comprehensive detector portfolio on the market

* Proportional counting detector simple coating thickness measurements

* The right detector for the right application

* Silicon PIN diode for more sophisticated layer thickness measurements and simple material analyses

* Silicon drift detector for measuring the thinnest layers and precise analysis of the elemental composition of materials

The proportional counting detector offers the best measurement performance when dealing with a large measurement distance or a very small measurement spot for simple coating thickness measurements.

For more demanding coating thickness measurements and simple material analyses, the silicon PIN diode is the right choice.

The silicon drift detector (SDD) can be used to measure layer thicknesses in the nanometre range and complex multi-layer tasks as well as to precisely analyse the elemental composition of materials.

The calibration laboratory of Helmut Fischer GmbH is the First & Only Company in Germany to be accredited to DIN EN ISO/IEC 17025 for the mechanical measure and “mass per unit area”.

DAkkS Calibration Laboratory: ISO/IEC 17025 certified standards by and from Fischer

Complete traceability of the standards produced to national standards

ISO/IEC 17025 certification of customer material

The Fischer calibration laboratory is a competent calibration laboratory – according to DAkkS!

This means that accreditation in accordance with DIN EN ISO/IEC 17025 for the mechanical measurand “mass per unit area” guarantees the complete traceability of the standards produced to national standards.

The measured values obtained are therefore absolutely reliable and comparable regardless of the method, device and location used.

Exclusive Service: We can also certify your unique sample according to DIN EN ISO/IEC 17025.

You can benefit from Fischer’s comprehensive measurement expertise for the optimal solution of your measurement task – and at the highest possible standard worldwide.

At Fischer, you get full measurement expertise from a single source: in addition to our comprehensive portfolio of XRF analysers and services, we have around 500 certified calibration standards permanently in our range. With us, you will find the right solution for almost any measurement task.

We repeatability meet the highest quality standards! Our quality management system has been DIN EN ISO 9001 certified since 1997. The Fischer calibration laboratory is accredited for the mechanical measurand “mass per unit area” according to DIN EN ISO/IEC 17025. As a DIN member since 2016, we are also actively involved in the development of standards such as IPC 4552 (ENIG).

Helmut Fischer Foundation

The Helmut Fischer Foundation is the owner of Helmut Fischer GmbH and offers our company full financial independence, security and long-term stability – a real anchor.

The foundation also promotes science, research, education and the arts. For example, it supports the “Jugend forscht” competition and annually awards the Helmut Fischer Prize for Science Communication of the Deutsches Museum.