- PARKER MAGNETIC COILS – portable magnetizing coils for MPI

- FOERSTER update the software on their tried & tested Magnatest D 3.623

- FISCHER setting new standards FISCHERSCOPE® X-RAY XDV®-µ PCB & XDV®-µ WAFER.

PORTABLE MAGNETIZING COILS

Parker’s portable magnetizing coils are designed for magnetic particle inspection of ferrous metal parts. The coils allow for the use of either dry powder or wet inspection media and may be used for demagnetizing as well.

The coils are moulded in a tough black polyurethane and comes equipped with a Foot OR optional Hand switch and 3m neoprene power cord. The sealed electrical connection box has a 50mm X 127mm flat base allowing the coil to stand in a vertical position.

The pl-8s & pl-10s operate from a standard 240vac, single phase grounded power source.

To demagnetize a part after inspection, simply place the part within the coil near the outer circumference. While the coil is energized, remove or pull the part approximately 600m away from the coil before turning the coil off. Larger parts may be demagnetized by placing the coil directly over the part and withdrawing the coil in the same manner. Residual de-magnetization is not always possible due to the material composition.

The coils are designed for a 50% duty cycle, or approximately 2 minutes on and 2 minutes off. The coils are equipped with an internal thermal switch. But be aware like any coil or yoke continuous operation may cause overheating and damage the unit or power switch.

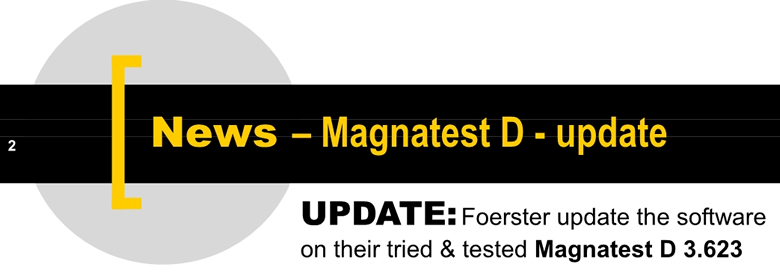

Processor-controlled compact unit with maximum performance

MAGNATEST D is the most commonly used system in the world for fully automatic magnetic induction testing of material properties in single coil absolute mode in the automotive sector. The combination of high excitation currents and complex evaluation electronic equipment detects even the smallest structural discrepancies. The test results are documented via test piece statistics, histogram, and test data export, which are displayed clearly on the touch display.

MAGNATEST D can be completed with an optional multiplexer for electronic switching in multi-coil operation. The unit also has a port for connecting it to superordinated quality management systems. The Magna-Claris software can also be used for the linear regression of a maximum of 250 calibration parts. This software can also calculate technological dimensions.

Your advantages at a glance

- Processor-controlled testing system

- Single coil absolute operation, therefore no comparison coil required

- Optional adapter for two-coil differential operation

- Load-independent induction current, therefore constant induction current intensity and constant magnetic field strength during the testing

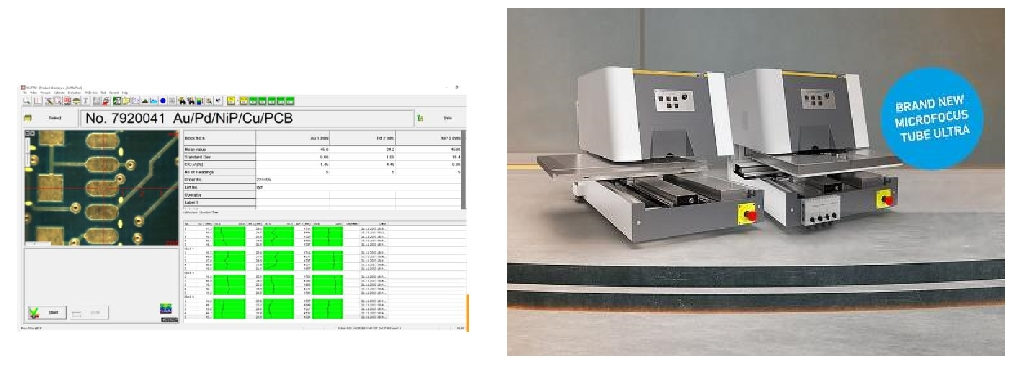

The Helmut Fischer Group is setting new standards with the further development of the FISCHERSCOPE® X-RAY XDV®-µ PCB and XDV®-µ WAFER devices.

Superior performance: The impressive high-end series from Fischer now has even better performance.

As of now, the FISCHERSCOPE® X-RAY XDV®-µ PCB and XDV®-µ WAFER devices not only have a new design, but also impress with a significant performance boost. Equipped with the new microfocus tube Ultra and the highly efficient digital pulse processor DPP+, users now benefit from a significantly reduced measurement time without any loss of precision compared to the previous models.

With the FISCHERSCOPE® X-RAY XDV®-µ, XDV®-µ LD, XDV®-µ PCB and XDV®-µ WAFER products, the FISCHERSCOPE® X-RAY XDV®-µ series comprises the most powerful XRF analysers in the Helmut Fischer Group’s portfolio. They are now all equipped with the new micro-focus tube Ultra as standard for even higher measurement performance with smallest spots. In combination with the powerful digital pulse processor DPP+ for efficient processing of higher count rates and the large-area silicon drift detector (SDD), the devices demonstrate maximum precision even with short measurement times.

Highest intensity for smallest spots

The XDV®-μ series is highly successful on the global market in the field of precise coating thickness measurement and material analysis of highly complex multilayer systems on the smallest components and microstructures. While the FISCHERSCOPE® X-RAY XDV®-µ PCB is specialized in PCB and the FISCHERSCOPE® X-RAY XDV®-µ WAFER in wafer measurement, the FISCHERSCOPE® X-RAY XDV®-µ and XDV®-µ LD were developed for coating thickness measurement and material analysis on chip and electronic components such as plug contacts, lead frames, bonding wires, SMD and solder bumps.

Our speciality for microscopic structures

All devices in the series are equipped as standard with our in-house produced Polycapillary Optics, which enable tiny measuring spots of down to 10µm full width at half maximum (FWHM) in combination with maximum intensity. The fact that the excitation unit in the new generation of the FISCHERSCOPE® X-RAY XDV®-µ series with the brand new microfocus tube Ultra has now been decisively optimized is particularly evident in the high-energy range. Smaller measuring spots can now be measured with even higher intensity, which catapults the effectiveness of the measurement into new dimensions. Users from the electronics & semiconductor industry will therefore experience a decisive advantage in the quality inspection.