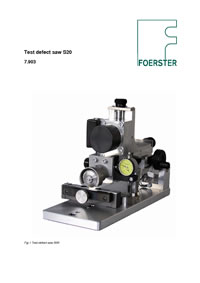

International standards like EN 10246 define artificial test defects to fulfil a high quality level. The production of notches in longitudinal direction with specified depth, width and length is common practice for calibration. Now FOERSTER offers a practical solution for precise sawing of transverse defects. It is possible to produce external defects in metallic wires, tubes and bars with dimensions from 1 – 20 mm.

Just one clamping is necessary for sawing of longitudinal and transverse defects via the innovative Twist-Clamping-Set technology. This permits a uniform and reproducible defect depth for longitudinal and transverse defects. Fine grading of Twist-Clamping-Sets permits perfect fixing of the test material and the setting to zero-point (saw blade gets in contact with test material).